Application–Vehicle industry

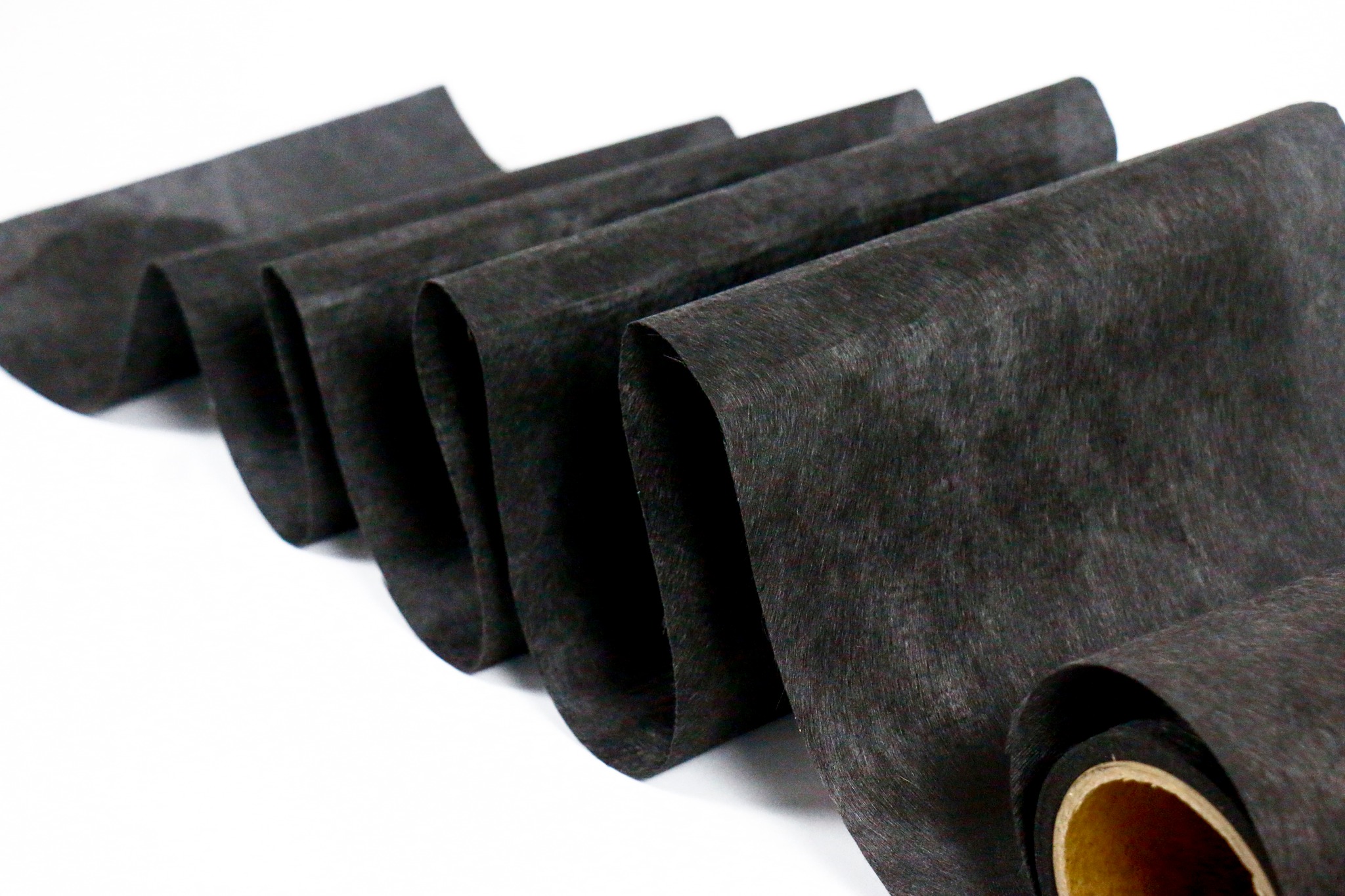

Carbon fiber nonwovens are widely used in vehicles. It can be used to manufacture vehicle bodies, roofs, doors, cabin sound insulation materials, seat supports, and other components. The lightweight and high strength of carbon fiber nonwovens allows vehicles to reduce weight and improve fuel efficiency and performance.

Carbon fiber nonwovens are indeed extensively used in various applications within the automotive industry due to their exceptional mechanical properties and lightweight nature.

Structural Components: Carbon fiber nonwovens are employed in the manufacturing of structural components such as chassis, body panels, and frames. Their high strength-to-weight ratio helps improve the overall strength and rigidity of the vehicle while keeping the weight down, thereby enhancing fuel efficiency and performance.

Interior Components: Carbon fiber nonwovens are also used in creating interior components like dashboards, center consoles, and door panels. These components benefit from carbon fiber’s sleek appearance and lightweight properties, contributing to a more modern and premium feel inside the vehicle.

Exterior Components: Carbon fiber nonwovens find their way into exterior components like hoods, roofs, spoilers, and mirrors. These components not only reduce the vehicle’s overall weight but also enhance its aerodynamics, leading to improved handling and efficiency.

Brake Systems: Carbon fiber nonwovens are employed in the manufacturing of high-performance brake components, such as brake discs and pads. The excellent heat resistance and thermal conductivity of carbon fiber help dissipate heat generated during braking, improving the performance and lifespan of the braking system.

Suspension Components: Carbon fiber nonwovens can be used to create suspension components like springs and control arms. These components offer reduced weight, leading to improved suspension responsiveness and handling characteristics.

Battery Enclosures: In electric vehicles (EVs) and hybrid vehicles, carbon fiber nonwovens are used to create lightweight and strong battery enclosures. This ensures the safety of the battery pack while minimizing the impact on the vehicle’s overall weight.

Noise, Vibration, and Harshness (NVH) Reduction: Carbon fiber nonwovens can be used in the insulation and soundproofing of vehicles to reduce noise, vibration, and harshness levels, leading to a quieter and more comfortable driving experience.

Performance Enhancements: High-performance vehicles often utilize carbon fiber nonwovens to improve acceleration, handling, and overall driving dynamics. Carbon fiber’s stiffness and low weight contribute to enhanced vehicle performance.

Fuel Efficiency and Emissions Reduction: The lightweight nature of carbon fiber nonwovens helps improve fuel efficiency by reducing the energy required to propel the vehicle. In turn, this contributes to lower emissions, aligning with environmental and regulatory standards.